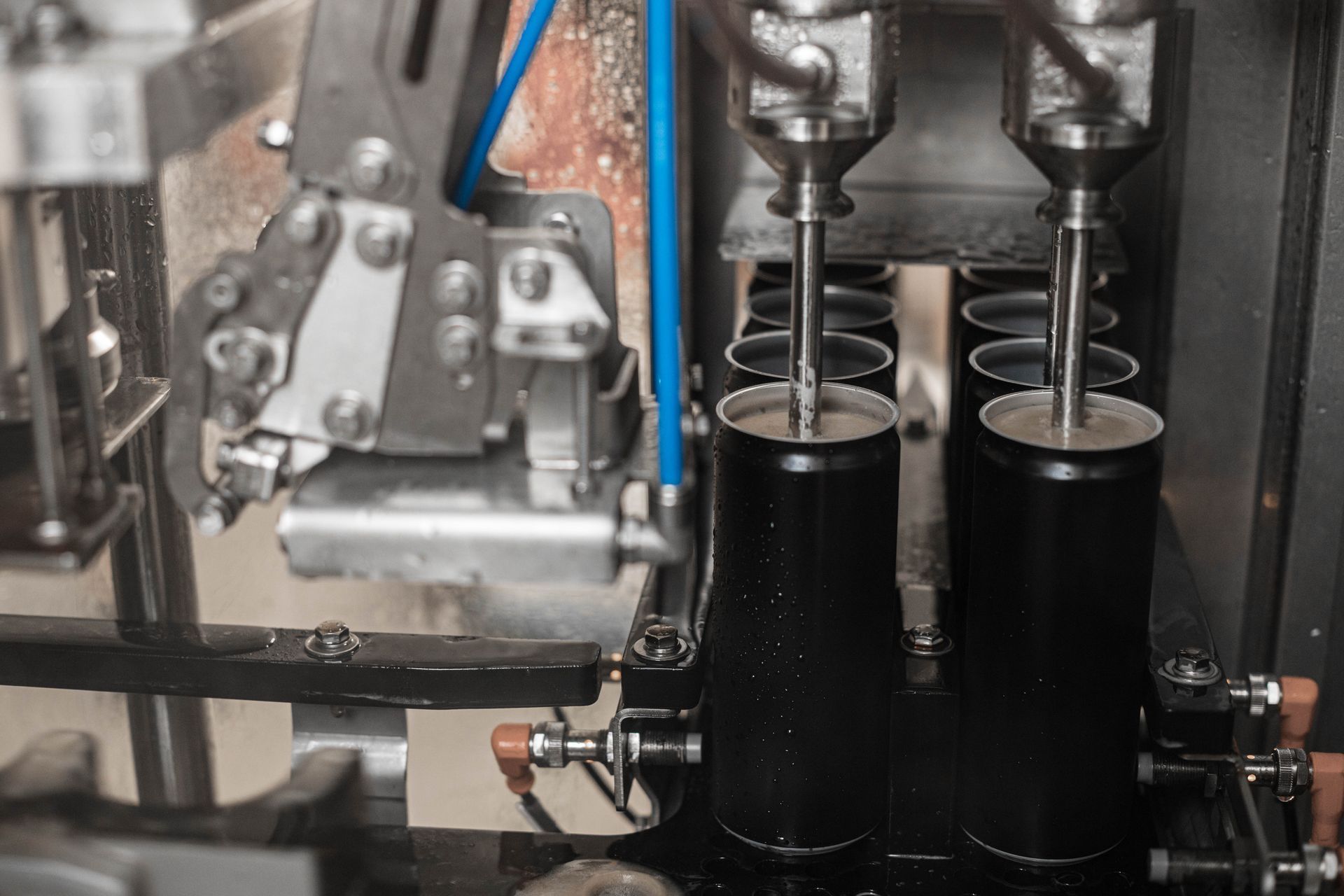

- Is the machine automatic?

- The CF2 machine is semi-automatic, it is necessary to push two cans at a time into the inlet: all other operations thereafter are automatic.

- Does it handle isobaric beer?

- The machines handle carbonated beer without any problems, up to 5.5 grams/litre of CO2 (carbon dioxide)

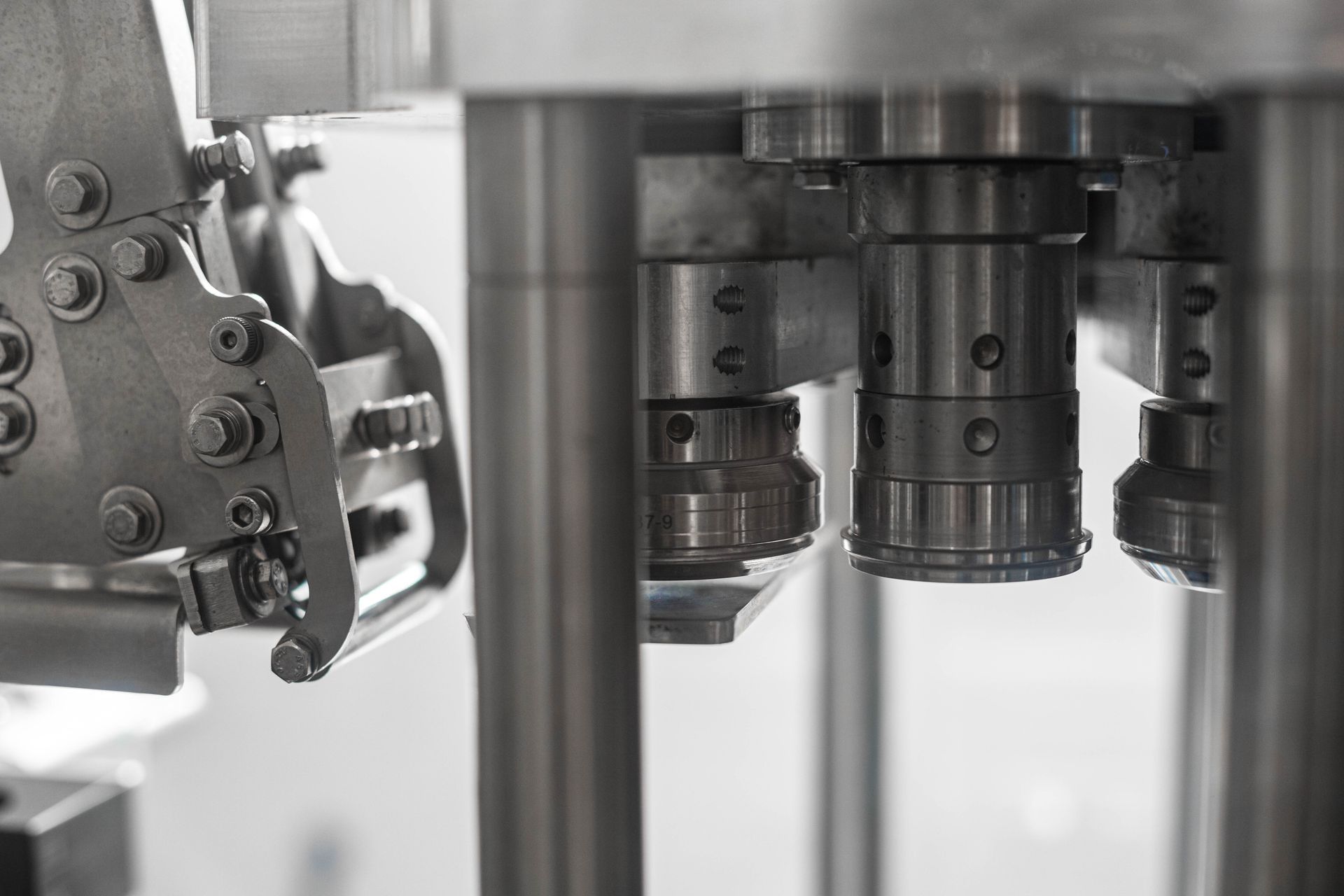

- Does the machine close the can?

- The machine fills, crimps (closes) and finally rinses the can externally

- Does the machine rinse the incoming cans?

- No, but it is always possible to add an external device to rinse the cans before they enter the machine.

- Does the machine label the can?

- Filling machines do not put a label on the can, but can be put in line with a labelling machine.

- What does the hourly speed of the machine depend on?

- On the type of product and its carbonation.

- Can the machines be customised for specific requests?

-We are able to design and integrate complete systems in response to our customers' specific requirements.

- Can I see the machine in operation?

-We are happy to provide contacts of our customers to watch the machine in operation.

- Can I operate the machine directly from a drum?

-Yes, filling from pressure tank, non-pressure tank or drum is possible.

- Is valve flushing difficult?

-No, valve flushing is very simple: they are set up for a recirculating CIP that minimises the amount of flushing solution used. The valves are also set up for bi-directional flushing.

- Can I do more than one can format with the same machine?

-Yes, the machines are supplied for 1 (one) can format but on request it is possible to do more than one format with the same machine.

- Are the machines made in Italy?

-Yes, all machines are of Italian design, development and production.

- How long is the warranty?

- The warranty on all our machines is 1 year.