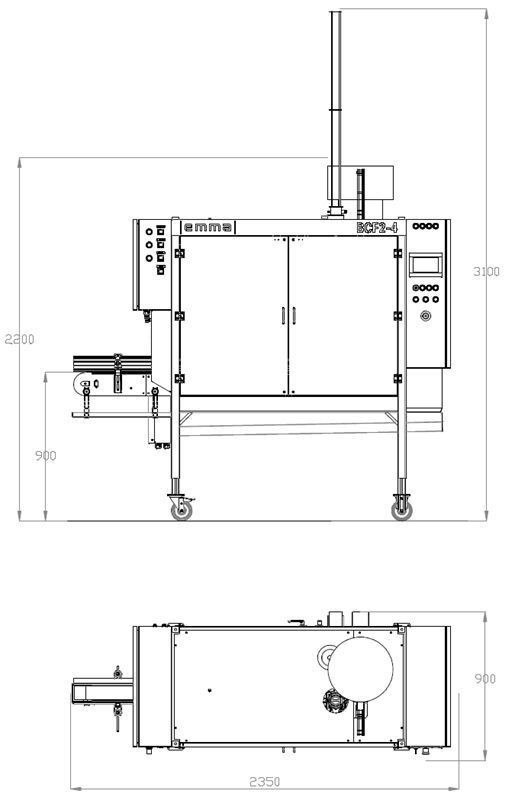

bCF4

CAN AND BOTTLE FILLING MACHINE

BCF4 is an automatic filling machine for cans and bottles. It integrates 2 to 4 gravity filling valves, a can seamer and a bottle capper.

TECHNICAL FEATURES

INNOVATION AWARD 2024

During the BBTECH EXPO 2024 trade fair, our BCF4 won first prize in the 'Innovation product' category. An innovation that required a lot of effort, time and resources, but which received very positive responses just a few months after its inauguration.

BCF4 FOR HORECA BRENTA (VENETIAN COURTS)

EMMA SRL CANNING SYSTEM

The craft beer

Corti Veneziane

is named after the project to create the beer of Venice using exclusively Venetian malts according to the ancient traditional method. A superior quality beer, which is brewed both in bottles and cans with the BCF4, our combination machine.

EMMA FILLING MACHINES CAN HANDLE CANS OF ALL FORMATS

You can make more than one can format with the same machine, the machines are supplied for 1 (one) can format but on request you can make more than one format with the same machine.

Interested in our services?

Contact us to illustrate us your needs!

Together we will find the best solution for your automation